Top 3 energy-efficient technologies of the near future in Russian retail

Modern energy-efficient technologies in the cold supply allow retailers to seriously save money and direct additional resources to the development of the network. In his last article, Sergey Pleshanov, Technical Director of Land, told about 7 energy-saving technologies that pay off quickly - up to 3 years – and should be used in all technical tasks when equipping modern stores. In the new material, he describes the top 3 technologies that have already begun to be used and will be widely used in Russia in the near future. Retail should take a serious look at them.

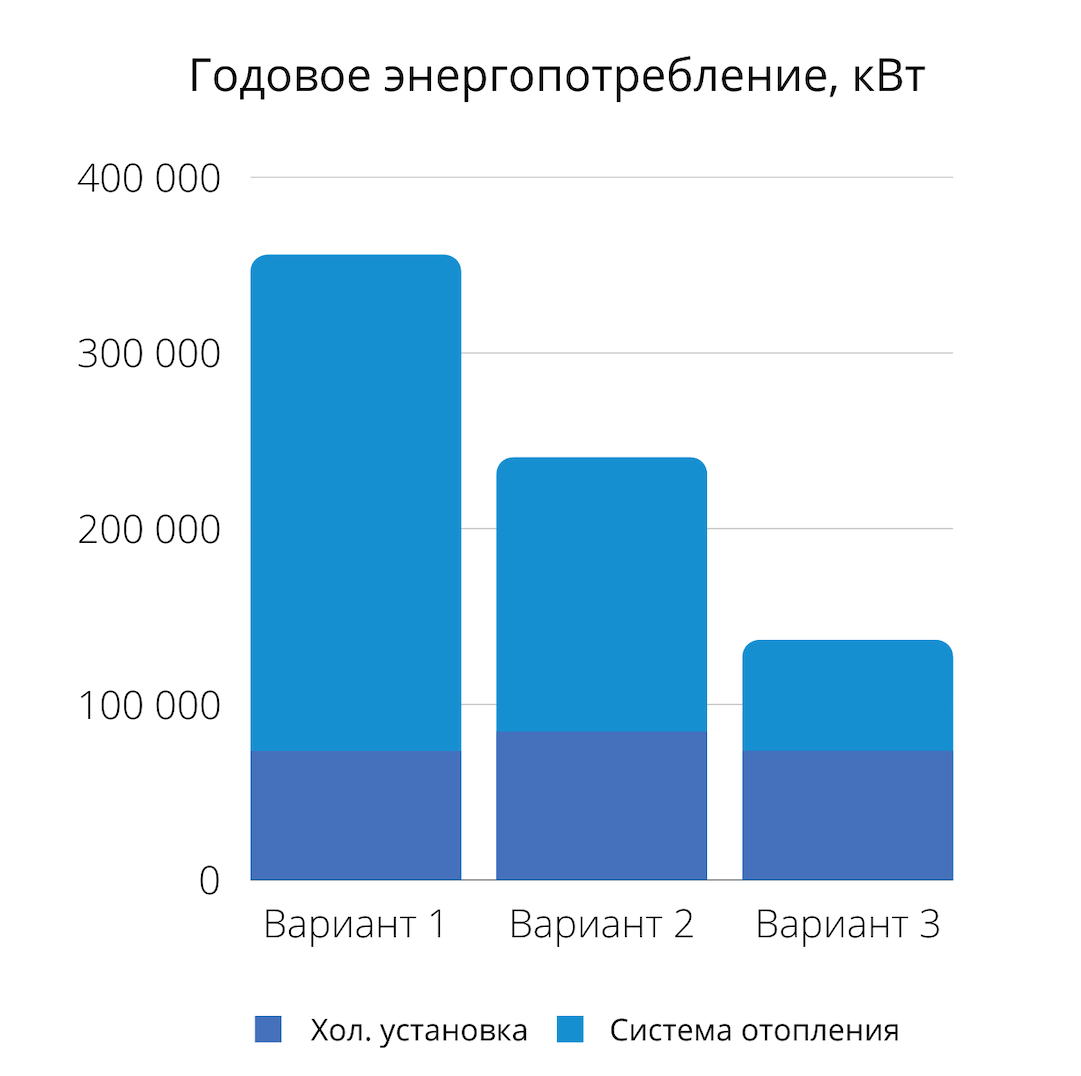

The figure above shows three main technologies that are just beginning to be used at retail facilities. Such solutions will certainly find their wide application, so the issue of technological transition is in the near future.

1. Carbon dioxide refrigeration unit

The most effective and environmentally friendly alternative to the commonly used refrigerating agent is carbon dioxide (CO2).

The prospects of CO2 refrigerant in retail and the cases of Metro, Auchan, dark store Perekrestok for the Future have already been discussed in detail in one of the previous articles.

There are many fundamental reasons for the widespread use of CO2 as the main refrigerant in shop building, let's consider only the main ones.

The Russian Federation has adopted the Kigali Amendment to the Montreal Protocol on Substances that Affect the Global Warming of the Climate of our Planet. The amendment will enter into force for Russia from January 1, 2021, providing for an individual plan for a phased reduction in the use of freons - by 5% annually. In Europe, this path has already been passed, as a result, the cost of refrigerant R404 has increased several times (see Table 1). All this increases interest in the use of carbon dioxide as a refrigerant in Russia.

Carbon dioxide has a high heat capacity, which, if used as a refrigerant, allows achieving excellent efficiency indicators - on average from 15 to 27% compared to systems on R404A. Using the example of GM Auchan Pushkino, CO2 technologies can save up to 422 thousand kWh per year, or 2 million 745 thousand rubles. during exploitation.

A distinctive feature of the carbon dioxide refrigeration cycle is the ability to obtain significantly more heat compared to the freon cycle, while not increasing electricity consumption. The figure below shows a graph of the cost of various heat sources per 1 kW.

Currently, carbon dioxide is used in large retail formats - super and hypermarkets, while the maximum energy-saving effect is achieved in low-temperature cold and when using heat recovery from a refrigeration unit to heat the trading floor or hot water supply.

The experience of Land company shows that the cost of CO2 equipment decreases annually, while the cost of freon systems is constantly growing. Taking into account the adopted environmental amendments, in the near future this will create all conditions for the use of carbon dioxide in the mass segment in discounter formats. If the period of return on investment in small formats is reduced to 3-5 years, we will get widespread use of CO2 in shop building, as is happening in Europe now.

Grigory Rashepkin, Head of the operation and reconstruction of refrigeration systems, Metro Cash&Carry, said: "Our company decided several years ago to use carbon dioxide. On the one hand, this was done in order to reduce the negative impact on the environment. On the other hand, we see the transition to natural refrigerants as an opportunity to gain competitive advantages in the future. We launched the first facilities according to a subcritical scheme, where CO2 is used only for low-temperature consumers, which made it possible to significantly reduce the amount of freon in the system and prepare a smooth transition to transcritical systems. Today we see that transcritical technologies allow us to increase the level of energy efficiency of the system, providing the store with heating and hot water supply. For Metro Cash&Carry, the project at the Solntsevo store provides a good opportunity to test theoretical calculations in practice, evaluate the features of the integrated use of the advantages of the transcritical CO2 system and decide on the optimal configuration of the system for subsequent stores within the current schedule for reducing the consumption of HFC refrigerants."

2. Heat pump and store heating

The shortage of electrical power and the lack of an affordable heat source are the most common obstacles to making a positive decision to open a store, even in a geographically attractive location. This fact forces store owners to pay attention to alternative ways of heating and getting hot water. There can be many options here: this is the utilization of condensation heat, electric boilers, and the use of a thermal air or geothermal pump.As practice shows, the most effective way of heating is a heat pump.

Option 1. The energy consumption of the electric boiler is so high that the savings due to the reduction of the condensation pressure of the refrigeration unit in winter are almost invisible inside the total energy consumption.

Option 2. The use of condensation heat for partial compensation of heat loss significantly reduces the energy consumption of electric heaters and the total energy consumption of systems, despite the overspending caused by the operation of the refrigeration unit with increased condensation pressure. However, in the case of using energy-saving closures on refrigeration furniture, implying a reduction in the thermal load on refrigeration equipment, and therefore the amount of heat condensation, the effectiveness of this option is also reduced.

Option 3. The most attractive from the point of view of theory. The presence of a heat pump allows the refrigeration unit to operate in the most economical mode. Although the efficiency of the air heat pump decreases with a decrease in the outdoor temperature, its energy consumption is much lower than when heating from an electric boiler.

The heat pump, spending 1 kW of electricity, allows you to remove up to 4.2 kW of heat. Electric heating under the same conditions, spending 1 kW of electricity, allows you to get 0.9 kW of heat. The system with a heat pump can operate at an outdoor temperature of up to (- 30oC), which makes it applicable for a fairly wide range of regions of the Russian Federation.

The electronic control system "Danfoss" allows you to simplify the setup as much as possible and avoid the need for additional adjustments during operation, and also ensures accurate maintenance of the required temperatures in all controlled heating zones of the room. Such solutions are already widely used at existing facilities.

The joint developments of the Land and Danfoss companies were aimed at reducing capital costs and, thereby, reducing the payback period of new stores and complete reconstruction facilities.

It is known that the required cooling capacity of the equipment is reduced by 30% in the autumn-spring period and by 70% in the winter period, thus, part of the compressor equipment is temporarily or permanently disabled. At the same time, there is a significant need for heat in the store, which can be compensated by the released capacity of the compressors for cold. In the summer, all compressors work for cooling, while heating is not required. In the autumn period, there is a need for heat, which increases significantly in winter, while the refrigeration load decreases.

Thus, it becomes possible to reorganize the operation of the equipment in order to optimize the use of resources when the power released in winter from the refrigeration equipment goes to the heating of the store.

The figure shows a central station with an integrated heat pump, based on Dorin reciprocating compressors, providing cold supply and heating of the store. The system has no analogues in Russia and is currently undergoing its patenting. A wide range of models makes it possible to cover all the needs of small and medium-sized store formats.

At the All-Russian competition of the best projects in the field of refrigeration and air conditioning systems, held within the framework of the Climate World 2020 exhibition, Land's solution for the integration of heating and cooling systems was selected by experts as the most attractive and received an award in the nomination "Best Energy-efficient Heat Pump".

The solution with a heat pump allows you to fully heat the store using only electricity, but it is much more efficient than heating with electric boilers.

The payback period of a separate heat pump is on average 2.5-3 years, and when using an integrated heat pump with a refrigeration unit, the payback period does not exceed 2.5 years.

All that has been said about the heat pump is also well combined with the use of CO2 as a refrigerant, which provides an even higher heat potential compared to freons. Therefore, looking into the more distant future, we can expect the maximum energy effect from combining a CO2 refrigeration system and a heat pump.

Dmitry Medvedev, head of Engineering and Technical support of X5 Retail Group, who was directly involved in the development of the solution, notes: "Operational experience has shown that the use of a heat pump reduces the energy consumption of the store by 50% compared to electric heating. The presented combined installation of full heating and cooling of the store is the third generation of the store heating system due to an air heat pump, which has proven itself as a reliable and efficient solution in our network. The system has a number of significant advantages - reduction of capital costs due to optimal use of compressor power resources, connection to a centralized dispatching system allows you to optimize its operation mode and use it in conjunction with other store systems. In this scheme, hot gas defrosting of the external air cooler of the heat pump was used for the first time, which will significantly reduce operating costs and increase the speed of defrosting. We hope that such a system will not just solve the heating problem that arises when selecting retail space, but will bring significant economic benefits during the operation of facilities."

3. Smart Store

The concept of a "smart store" closes the list of technologies that are already being effectively used and will soon receive the status of standard solutions.A modern retail store, in addition to refrigeration equipment, is a complex of engineering systems, including air conditioning, lighting and heating systems. These systems are often managed manually by the store's staff. This type of control is not energy efficient, as it does not allow to adapt the operation of systems to changing external conditions – street temperature and illumination.

In modern conditions, the system of integrated automation of engineering systems of a grocery store, which allows implementing the concept of a "Smart store", is an additional opportunity to reduce operating costs, which means to gain competitive advantages in the food retail market.

The Danfoss MCX programmable logic controller is used to control thermal curtains, air conditioners, ventilation systems, outdoor and indoor lighting.

Heat curtains are controlled according to temperature and schedule with the possibility of blocking the heating mode during the warm season. For the air conditioners of the trading floor, a calendar schedule of work, a daily schedule and blocking changes in settings by personnel, as well as blocking the start at certain outdoor air temperatures are provided. Additionally, it is possible to switch between heating and cooling modes depending on the season.

The ventilation system is controlled according to an individual schedule with the possibility of stopping during the closing of the store.

The external lighting and the store sign are controlled by an astronomical timer depending on the time of sunrise and sunset at the location of the store; the internal lighting of the store is on an individual schedule with the possibility of extending the working time if necessary. There is also a special "Inventory" mode, for which you can specify the required date in advance.

Maximum energy savings in the case of a small format store can be achieved, including using the possibilities provided by the organization of a combined cooling system with an integrated heat pump. The use of integrated solutions both at the level of the control system and at the level of the hydraulic circuit of the refrigeration unit makes it possible to fully implement the concept of "smart store", which means to achieve a high level of efficiency of the store's engineering equipment.

It should be noted the flexibility of the control system and algorithms, which opens up broad prospects for further optimization for the needs of the store. In conclusion, I would like to say that the creation of a "smart store", the use of carbon dioxide as a refrigerant, as well as the use of the heat potential provided by the refrigeration system, are steps towards the goal of creating a store with zero energy balance.

Based on the calculated data, the organization of an integrated management system will allow to achieve a reduction in energy consumption of about 20-25% with a return on investment of up to two years. Such solutions are already being widely developed in large federal networks.

The head of the technical expertise and audit of the Pyaterochka retail chain, Ivan Borisov, spoke about the use of the smart store system: "Our company carefully approaches the issues of store efficiency. As you know, most of the electricity consumed by the store falls on refrigeration equipment. Therefore, we started the process of optimizing energy consumption with this type of consumer. And we have achieved significant success in this regard. We did not stop there and began to look for opportunities to obtain additional savings by optimizing the operation of other engineering systems, such as lighting, ventilation, air conditioning and heating systems. As it turned out, the management of these systems in manual or semi-automatic mode leads to overspending of electricity. Then we decided to follow the path of organizing a comprehensive automation system for the store's engineering systems, which allowed us to reduce its energy consumption by an average of 15-20%. But this is only part of the way: we continue to explore additional opportunities for savings, both at the level of control algorithms and in terms of introducing new technologies. To date, a decision has been made to install the system at each of the stores we open."

In conclusion, it should be said that each of the solutions presented above has been repeatedly tested and shows the most effective result in reducing the operating costs of the store. For its customers, Land Company necessarily conducts a technical and economic analysis with the provision of payback, so that the customer can comprehensively evaluate and make the right choice in favor of certain solutions.